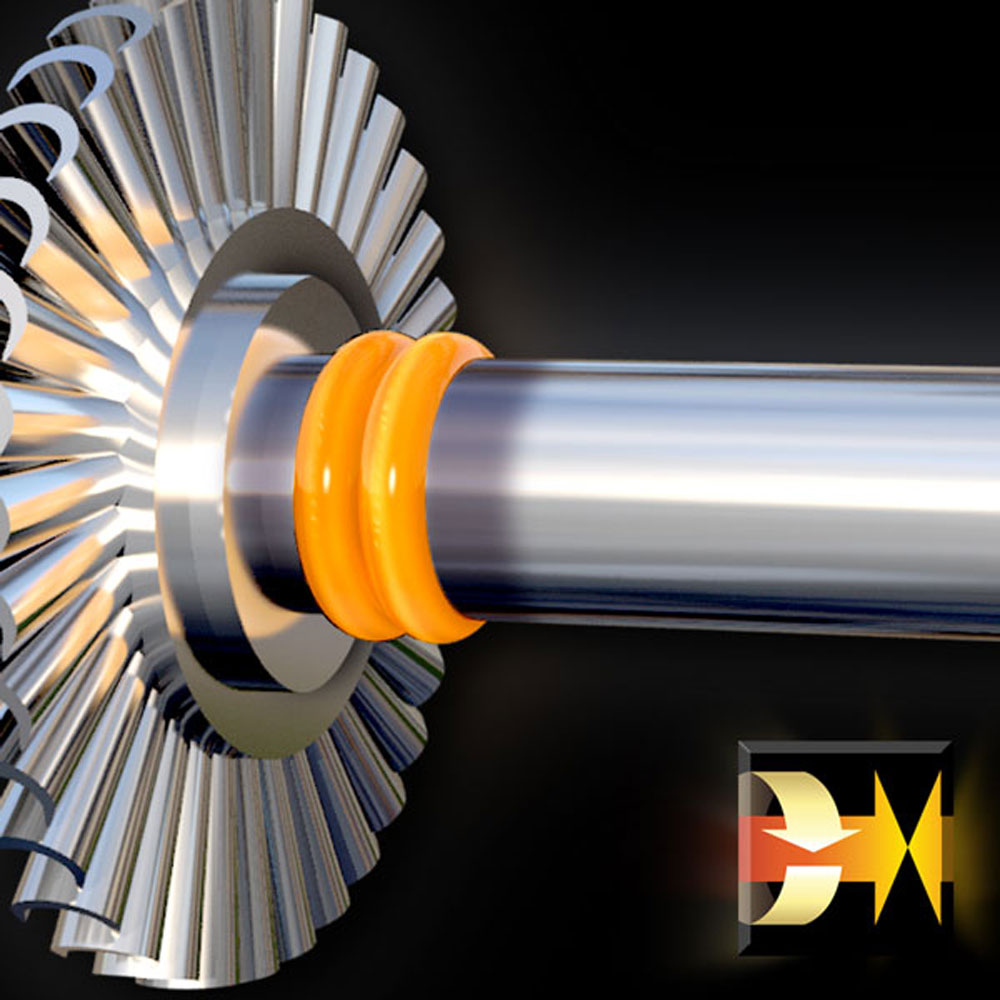

Friction welding provides a high-strength, cost-effective solution to join a shaft and turbine together. The result is complete metal fusion without the need for fluxes, fillers, gasses, or an external heat source. The solid-state process requires minimal joint preparation and eliminates the possibility of porosity or slag inclusion. The narrow heat-affected zone of the weld area protects the molecular integrity of both components. This bonding method offers consistent and repetitive results with faster production turn-around.

Cost savings result by reducing the amount of raw material, machining, and tooling required to produce a completed part. Design flexibility provides turbine construction from one metal and shaft selection from a lower cost stock or vice versa. The joining of dissimilar metals is possible where conventional methods may not work.

The AFW team will work with you to engineer the correct design solution and ensure superior strength for all critical part areas.

Click to view other examples of welding dissimilar metal shapes.