The Quality Standards of your Friction Welder are as critical as the benefits of Fiction Welding – let’s look at how important choosing the best Standard can be.

Three Standards are specified by the American Welding Society guidelines:

- Inspection

- Validation

- Data Acquisition & Record Retention

Critical to product performance and longevity, these standards need to be considered carefully as you choose your friction welding resource. Most friction welders will know about visual inspection and validation, but not all have real-time data acquisition on their machines and retain that data to ISO Quality Standards as we can do at American Friction Welding.

For example, you may have a high volume of parts in your inventory that has been friction welded and you suddenly receive word that a part failed in the field. The quality controls that were in place when your parts were welded can mean the difference in isolating a small batch for analysis versus an outright recall of all friction welded parts. The best way to mitigate this risk is to not only understand the levels of quality assurance AWS sets forth but asking and knowing what the highest level of assurance your friction welding source can provide.

You can expect AFW to perform a B1 level quality check at a minimum and to offer A1 or A2, based on your preference and never below these standards.

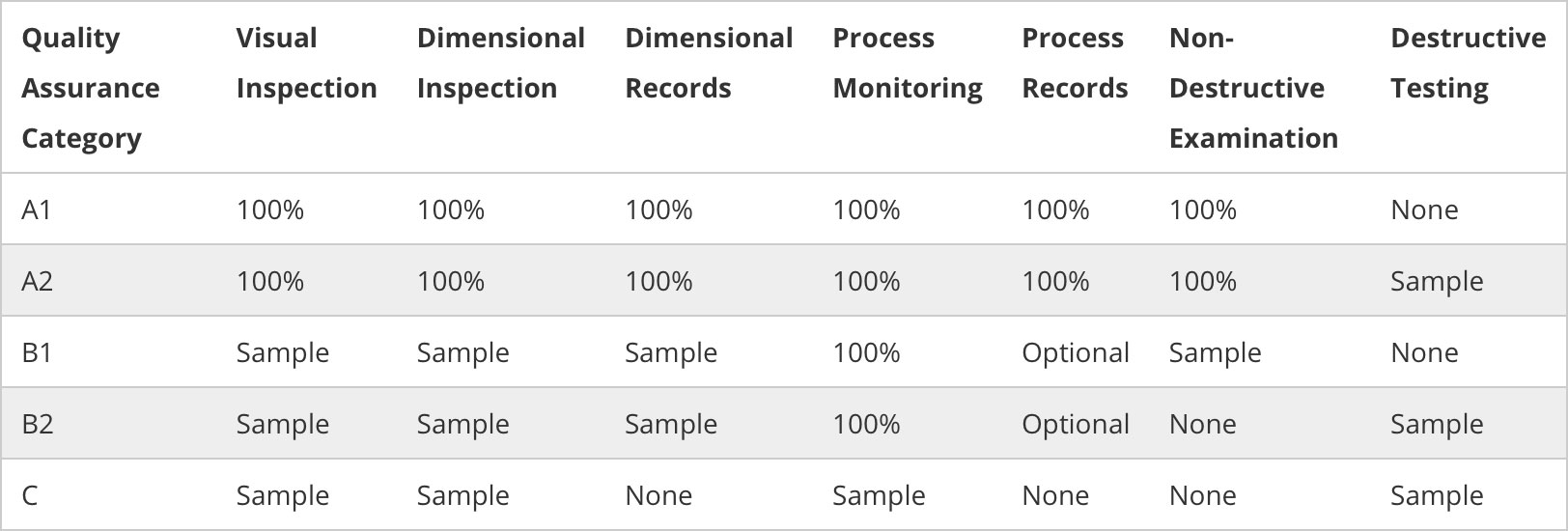

We encourage our customers and prospects to tell us what level of quality they prefer their welding projects to adhere to, and I encourage you to review the quality assurance categories and the table below to get a better understanding of what these categories entail. I will be happy to discuss details and what you can expect when specifying a level.

Production Quality Standards Categories

Category C – Only a sample of weldments will be visually and destructively examined, and shall have specified process monitoring parameters and dimensions checked. There are no recordkeeping requirements in regards to a parameter of dimensional traceability.

Category B2 – An agreed upon weld sample shall be checked visually. A bend test or other destructive test shall be performed on a specified sample of weldments. Specified process monitoring parameters for all weldments shall be within acceptable limits but not necessarily recorded. Physical dimensions for an agreed upon sample of the weldments shall be recorded and maintained for an agreed upon time.

Category B1 – An agreed up weld sample shall be checked visually and by an NDE method listed in the latest edition of AWS.

Category A2 – Every weld is checked visually and by an NDE method listed in the latest edition of AWS B1.10. In addition, a bend test or other destructive test shall be performed in accordance with the latest edition of AWS B4.0. Specified process monitoring parameters and physical dimensions for each weldment shall be recorded and maintained for an agreed upon period of time.

Category A1 – Every weld is checked visually and by an NDE method listed in the latest edition of AWS B1.10. Specified process monitoring parameters and physical dimension for each weldment shall be recorded and maintained for an agreed upon period of time.