Friction Welding Provides the Strongest Bond When Welding Rebar Together

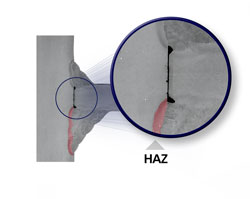

Friction welding is a superior method of welding rebar components. The solid-state joining process uses friction to generate heat to forge parts together without filler metals. The process clamps one piece while the other rotates in a chuck. The two pieces rub at the weld interface producing heat due to surface friction. Once the metal reaches a specific temperature and desired overall length loss, rotation stops, and the two pieces forge together with high pressure. This pressure causes the metals to fuse, creating a high-strength, permanent weld. The metals only reach a plasticized state before forging, creating a very narrow heat-affected zone (HAZ) protecting the molecular structure of the metals. Friction welding is strong as the parent materials, can bond dissimilar metals, and withstands high stresses and strains.

Rebar friction welding has several advantages. The quick and efficient process makes it a good choice for large-scale construction projects. Additionally, it creates a full penetration weld that is resistant to fatigue and can withstand high stresses and strains.

Friction Welded Headed Rebar

High-Strength Steel Threaded Tube-to-Plate Welding

Friction Welding vs. Conventional Welding

Friction Welding Cross-Section Closeup

Friction Welding Cross-Section CloseupComplete Metal Fusion of Surfaces

Conventional Welding Cross-Section Closeup

Conventional Welding Cross-Section CloseupVoids Between Bonded Surfaces

Metal Properties Change Due to High Temperature

Rebar, short for reinforcement bar, is a crucial component of concrete construction. It is a steel bar that provides support and tensile strength to concrete structures, such as buildings, bridges, and roads — typically made of carbon steel or stainless steel, known for its strength, durability, and resistance to corrosion. The size and shape of the rebar in a particular construction project depend on the structure’s intended use and the loads it will need to support.