Industry

Semi-Conductor

Product

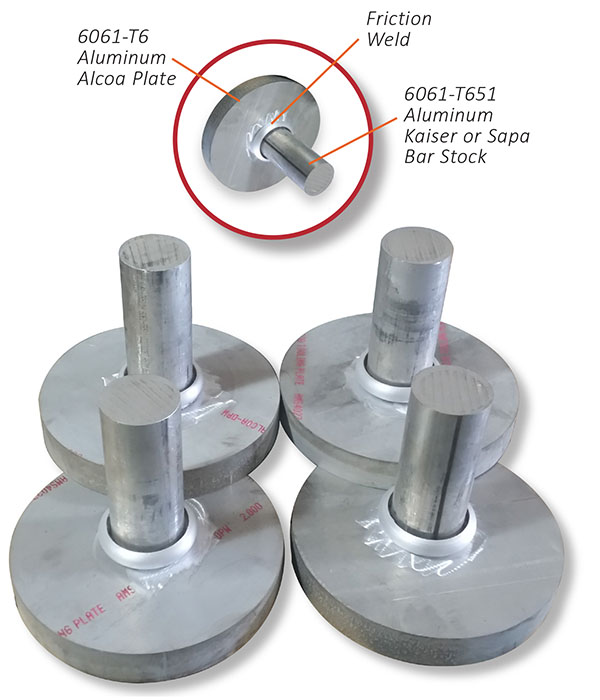

Shower Head Stem

Application

Uniform Distribution of Processing Gases

Challenge

A leading manufacturer of aluminum shower heads for the semi-conductor industry needed to reduce costs and increase machining capacity while maintaining a specific grain structure. Their current workflow is to turn down a 13” OD solid bar to a 3.5” shaft.

Solution

Utilizing The Friction Welding Advantage, American Friction Welding assisted the customer to realize a 42% savings on material and 150% increase in capacity by employing the following:

- Friction weld a 3.5” x 9.7” round to a 13” x 1.25” disc

- Increased the throughput time in the lathe from 2 piece hour to almost 8 / hour

- Maintain grain structure that was necessary for the 13” portion of the component while creating a solid state at the weld joint

Since these parts have a wide variety of gasses flowing through them the friction weldment needed to be re-tempered to its hardest state. Even after adding this heat treatment operation to the process the cost savings were still substantial.

Conclusion

Reducing material costs or increasing throughput have tangible impacts on the operational bottom line but friction welding can assist in solving design and engineering issues as well. Normally the cost savings alone in this instance will prove to be worthwhile and the enhanced functionality of the material structure will ensure that the part will operate as expected in its real world environment.

Contact us today to discuss your application in confidence and save with our unique capabilities!