Common Applications

Why Friction Welding?

Used by OEMs across multiple industries worldwide, friction welding holds numerous advantages over conventional welding, the most important being:

It’s More Cost-Effective!

You can save money across the board with our friction welding process:

- Friction welding doesn’t use consumables like filler metals, fluxes, gases, etc.

- Reduces machining labor, thereby reducing perishable tooling costs while increasing capacity.

- Reduces raw material costs in bi-metal applications – Saving money on expensive or rare materials.

Learn more about cost reduction and efficiency gains or lot size and cost savings.

Bonding Dissimilar Metals

One of the most significant incentives for adopting new friction welded designs are combining dissimilar materials.

- Conventional welding methods don’t allow the joining of different materials, but friction welding does, allowing exotic alloys in specific use areas!

View our Welding Dissimilar Metals Chart for detailed information.

Additional Benefits Worth Considering

The advantages of friction welding don’t end with lower costs:

- Faster turn-around times – compared to the long lead time of forgings, which are currently six months or longer.

- Suitable for diverse quantities – from single prototypes to high-volume production.

- Full surface weld – giving superior strength in critical areas for long-lasting durability.

- Consistent component quality – our friction welding process produces duplicate integrity through repeatable metal fusion.

Friction Welding Applications

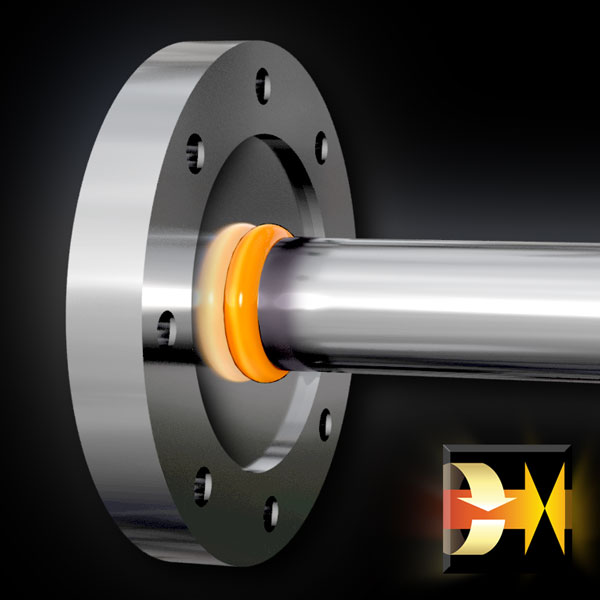

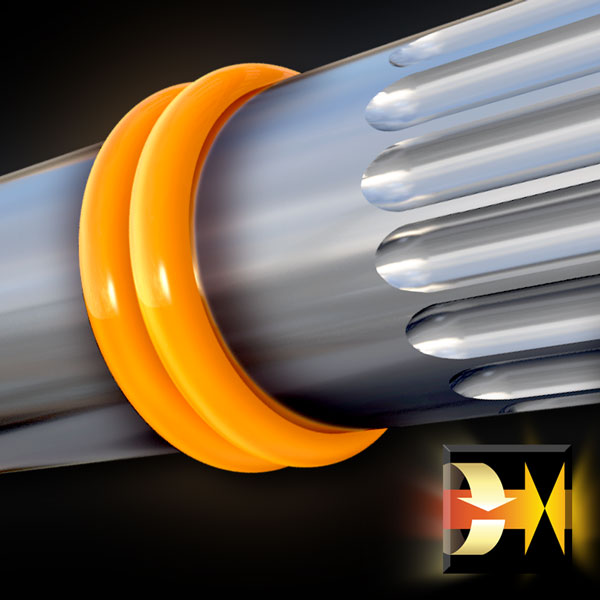

Typical applications are combining: axle shafts, bar stock sections, cast iron to steel components, discs to shafts, driveshafts, gears to shafts, hydraulic cylinder rod end, motor shafts, pipe to pipe segments, prop shafts, propeller shafts, rebar welding, round bar to pipe sections, round bar to round bar, round bar to tube, round tube to plate, shaft to shaft segments, solid round to pipe, solid round to solid round, solid round to tube, steering shaft, stub shafts, tube to tube sections, turbines to shafts, valve welding, and yokes to shafts.

As the largest full-service, direct-drive, rotary friction welding shop in North America, AFW delivers an unmatched experience, quality, and support from design prototyping and customized solutions throughout the entire production.

Our experts are ready to discuss how we can apply our friction welding process to your current fabrication needs.