Industry

Roller Manufacturer

Product

Rollers

Application

Printing Presses, Conveyors, Agricultural Equipment

Challenge

Leading roller manufacturer of printing, conveying and agricultural equipment needed to reduce roller material costs, weight and overall costs, while maintaining roller quality.

Solution

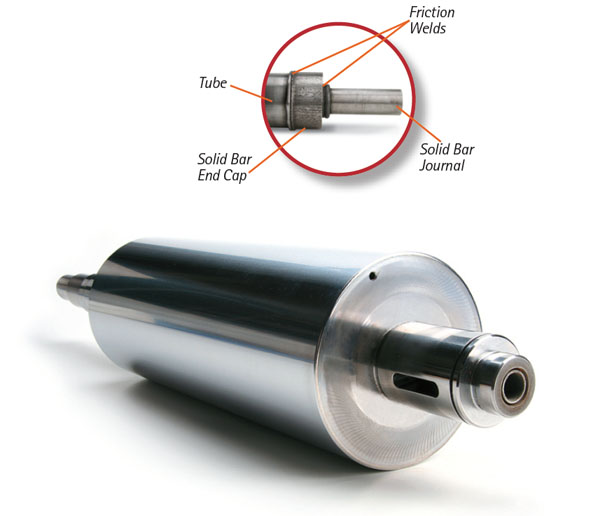

Utilizing The Friction Welding Advantage, American Friction Welding helped customers realize 15 to 35% costs savings, reduced weight of roller by 20 to 50% and increased strength and performance of finished rollers by employing the following:

- Friction welding tubing to saw cut end caps, then journals to end caps to create lightweight friction welded blank

- Reduced overall machining time by 15% by having near net shape blank

- Neither journals nor endcaps require special weld preparation

- Friction welded joints maintain strength and mechanical properties of parent materials throughout welded area

- Wide variety of metal combinations available

Conclusion

American Friction Welding application specialists work closely with you throughout your project. Design engineering assistance, process analysis and testing gives you the ultimate cost solutions. Add comprehensive post-production KanBan inventory and logistical support services and you’re surrounded with The Friction Welding Advantage from AFW!

Contact us today to discuss your application in confidence and save with our unique capabilities!