Destructive Testing

Destructive Weld Testing involves the physical destruction of the friction welded components. A variety of testing methods can be employed to evaluate the weld’s characteristics. We perform these tests on all prototype welds per customer specifications.

Sampling inspections of production welds are performed to:

- Qualify weld performance

- Troubleshoot using failure analysis

- Research inspection processes to improve or validate current testing methods

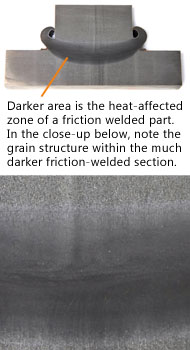

Cross-section examination of the weld quality

- Using a macro etch test (and depending on the base material(s) joined in the weld), a mild acid mixture is applied to the cross-section surface.

- The resultant etching provides an excellent study of the internal structure of the weld, which is also helpful in detecting welding problems.

Closeup of friction weld zone

Bend Test in Action

Identify Integrity Issues

- Depth of Penetration

- Lack of Fusion

- Inadequate Root Penetration

- Internal Porosity

- Cracking or Inclusions

Additional tests may be applied to validate ductility, soundness of welded joints, tensile strength or any presence of slag inclusions or weld quality discontinuities within the entire length of the weld.

Depending on the characteristics requiring inspection, we use various destructive test methods for friction welds:

- Bend Tests: free bend, guided bend, longitudinal bend, transverse bend

- Etch Test

- Hardness Tests: Brinell hardness, Rockwell hardness

- Impact Test

- Nick-break Test

- Tensile Test

- Torque Test

Threaded Rod Inspection

Cross Sectioned Tube

Non-Destructive Weld Quality Testing

Ultrasonic inspection is used regularly to ensure weld integrity. This test is performed per customer specifications.

Non-destructive testing also involves inspection of welded components by subjecting them to the required service conditions to determine suitability. These tests are designed to reveal defects that may impair service performance. They will not break or alter the structure or appearance of the friction welded piece.

Friction Welding Video

Nondestructive Testing