Consistent Quality

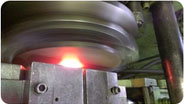

American Friction Welding is a world leader in friction welding technologies and contract welding solutions. We use four parameters to implement custom manufacturing processes, ensuring consistent quality of metallic bonds. Dimensional inspections assure conformity to specifications and engineering drawings.

1. Flexibility

Some of our customers require more flexibility from a friction welder because of fluctuations that commonly occur in their industry.

American Friction Welding routinely assists customers with their unexpected deadlines or customized friction welding projects (among other demands). Our team does not consider any of these as obstacles. Feel free to tell us about your special needs or circumstances.

2. Customer Care Responsiveness

AFW’s team of expert friction welders are always ready to help in critical situations. A major OEM serving the construction and agriculture industries experienced catastrophic damage to their friction welding equipment. While their new welding machine was on order, AFW quickly responded by providing critical friction welding support to minimize OEM part supply disruptions and production downtime.

AFW manufactured the required tooling within days and produced 4,800 welds over the next six months, demonstrating unique responsiveness in critical customer situations.

In another situation, AFW assisted a major producer of hydraulic cylinders when they faced similar machine challenges, and we responded accordingly.

3. Proactive Preparedness

As a proactive measure, we recommend that manufacturers keep us prepared for unexpected supply disruptions that may arise. One tactical consideration is to allow us to produce the required tooling and sample parts in advance. This preparation eliminates rush tooling charges, downtime, and loss of market share. With tooling and parts on-hand, we’ll be ready to step in if the unexpected events occur.

Call AFW to discuss more details about tooling and sample parts production… or perhaps other unique ways that we may assist with your strategic sourcing.

4. Expertise in Welding Dissimilar Materials

Dissimilar materials normally not compatible for welding can be friction welded.

Weld Production Quantities

Friction Welding is most often applied to repeat production of identical parts. Economically, friction welding is feasible from small lot size orders of 50 to 100 pieces all the way up to full time monthly production of thousands of pieces. Sometimes AFW produces one-off custom pieces when only friction welding can provide the strength of bond required for special material combinations.

Industries Served

- Aerospace

- Agricultural

- Automotive

- Gears

- Heavy Equipment

- Hydraulic Cylinders (agricultural and construction)

- Industrial Equipment and Machinery

- Mining

- Oil and Gas

- Power Generation

- Pumps (food processing, pharma, chemical, and fuels)

- Railroad

- Rollers

- Transportation

- Trucks (class 8)

In-House Tooling

We have a fully equipped in-house fixture and tool-making room. Our ability to internally engineer, build and maintain our friction welding equipment demonstrates our commitment to providing the support and expertise that our customers expect.

Extensive Industry Experience

In 1986, American Friction Welding began providing friction welding for the printing and computer industries. It was soon realized that our services could be applied to various industries and we could still provide customers with a quality product at a cost-efficient price. This proved to be a desirable and profitable implementation that has enabled us to expand our facilities to be one of the largest job shops in the USA.

American Friction Welding supports a wide variety of industrial applications from its 50,000 square foot, climate-controlled facility that is easily accessible to major interstates ensuring maximum logistics efficiency.

Learn More:

Manufacturing Engineers

- Increase throughput

- Save machine time

- Reduce material waste

- Maintain quality

Design Engineers

- Combine unique shapes

- Join dissimilar metals

- Reduce weight

- Increase part strength

Purchasing Agents

- Diversify your sourcing

- Reduce lead times

- Eliminate die expenses

- Buy less material