American Friction Welding (AFW) is North America’s largest subcontract friction welder with 18 high-precision friction welding centers. We are experts at welding dissimilar metals and near-net-shape parts using direct-drive rotary friction welding to deliver full-strength, deep-penetration welds in the most demanding applications and industries. Dramatic cost savings result from reducing the working material, machining, and surface finishing needed to produce finished metal components.

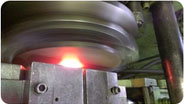

Rotary friction and inertia welding is a solid-state process joining two metal components by applying rotational motion and forging pressure to the objects. High temperatures generated by friction transform the point of contact into a plasticized state. This area is known as the weld interface. The pressure is applied to forge a metallic bond between the atoms of the objects. The overall molecular integrity of the original components remains intact due to the narrow heat-affected zone of the technology. Friction welding provides a complete cross-sectional bond without using fluxes or filler metal. Metal spin welding or rotary welding cycle times vary by metal type, shape, and weight.

We specialize in friction welding aluminum alloy, brass, bronze, copper, nickel, silver, steel alloy, carbon steel, stainless steel, tantalum, titanium, tungsten, and many other metal alloys. One object spins at a controlled rotating speed while the other is stationary. Friction heats the dissimilar material where they contact. It successfully bonds two different metals where conventional means may not work. It provides a high-speed, lower-cost solution to join motor shafts, axle shafts, prop shafts, gear to shaft, disc to shaft, solid round to solid round, pipe to pipe, solid round to pipe, and many other dissimilar shapes. The joining process is an alternative to brazing, electron beam, explosive, and butt welding methods.

|

Friction Welding Continues to Increase Its Dependability John Fischer, president of AFW, recently wrote an article for the Welding Journal titled “Friction Welding Continues to Increase Its Dependability.” Download your PDF copy to learn about the advantages and recent advancements of the rotary friction welding process. |

AFW is ISO 9001:2015 Certified in manufacturing custom friction welded assemblies and providing the services of material procurement, friction welding, CNC machining, and customized inventory programs. The company has a fully dedicated quality manager and a quality department. Our dedication to quality is absolute and without compromise as we focus on delivering the highest quality products and services.

We emerged as the industry leader with a 100% customer satisfaction focus, state-of-the-art manufacturing equipment and processes, and a dedication to quality that is second to none. Every part we produce adheres to a Weld Procedure Specification (WPS) that dictates acceptable manufacturing tolerance parameters. Our welding centers, equipped with advanced high-precision controllers, monitor every critical variable during the weld cycle to ensure product conformance. Each cycle is measured, with data recorded for future parameter review. Our quality assurance team performs ultrasonic weld inspection on a minimum of 10% of all parts produced to ensure conformance and quality of working materials.

View our quality control and ISO 9001 certification.

A climate-controlled facility delivers another level of consistency to our manufacturing process. Repeatable bonding relies on controlled conditions, which include its environment. All working materials acclimate to operating ambient temperature before production, per approved WPS.

A climate-controlled facility delivers another level of consistency to our manufacturing process. Repeatable bonding relies on controlled conditions, which include its environment. All working materials acclimate to operating ambient temperature before production, per approved WPS.

Our full-time maintenance team manages over $200,000 of spare manufacturing equipment parts. They provide preventive and predictive maintenance, minimizing unscheduled downtime and increasing the on-time delivery of your product.

Our full-time maintenance team manages over $200,000 of spare manufacturing equipment parts. They provide preventive and predictive maintenance, minimizing unscheduled downtime and increasing the on-time delivery of your product.

AFW partners with customers to provide turn-key solutions for their long-term manufacturing programs – Offering a competitive advantage through efficient supply chain manufacturing, a continuous improvement focus, and unmatched customer service.

AFW partners with customers to provide turn-key solutions for their long-term manufacturing programs – Offering a competitive advantage through efficient supply chain manufacturing, a continuous improvement focus, and unmatched customer service.

Friction welding dates back to the mid-50s - 63 years ago. For 33 years, AFW has served as an advocate, standards contributor, and driving force of industry development. The technology has evolved into a sound joining alternative providing design flexibility and cost savings across all manufacturing channels. Our engineering team is here to provide straightforward answers, guidance, and solutions. When friction welding is the solution - AFW is the company to trust!